Our triple distilled single malt is made from 100% malted heritage barley. Our water comes from a well onsite that is filtered down through the layers of rock from Benbulben mountain and the surrounding area, granting a flavour unique to the West Coast of Ireland.

Malting

A barley grain is like a small factory and, under the right conditions, it will convert its stored-up starch into sugar and then sugar into cellulose, in order to grow roots and a germ with leaves. This process is called germination. Malted barley is simply barley that has been moistened and stored in a warm, damp environment to fool the barley into starting to grow. Over the next 5 days the germinating barley releases enzymes that begin converting the starch in the barley into sugar. The barley must be constantly moved to ensure an even growth and to guard against mould formation. After the enzymes inside the grain have started to transform the starch into sugar the germination process is halted. This is done by quickly drying the barley in a large kiln, until only 4% moisture remains. The resultant, partly germinated grain, is now called malted barley or simply “malt”. We buy ours from growers on the Hook Head Peninsula in County Wexford. It is delivered by truck, which empties the malt into a hopper outside the building and computer-controlled conveyors bring it into our grain storage area. We store it in 3 grain silos each capable of holding a full truck load of 25 tons, which is enough grain for about 10 days production.

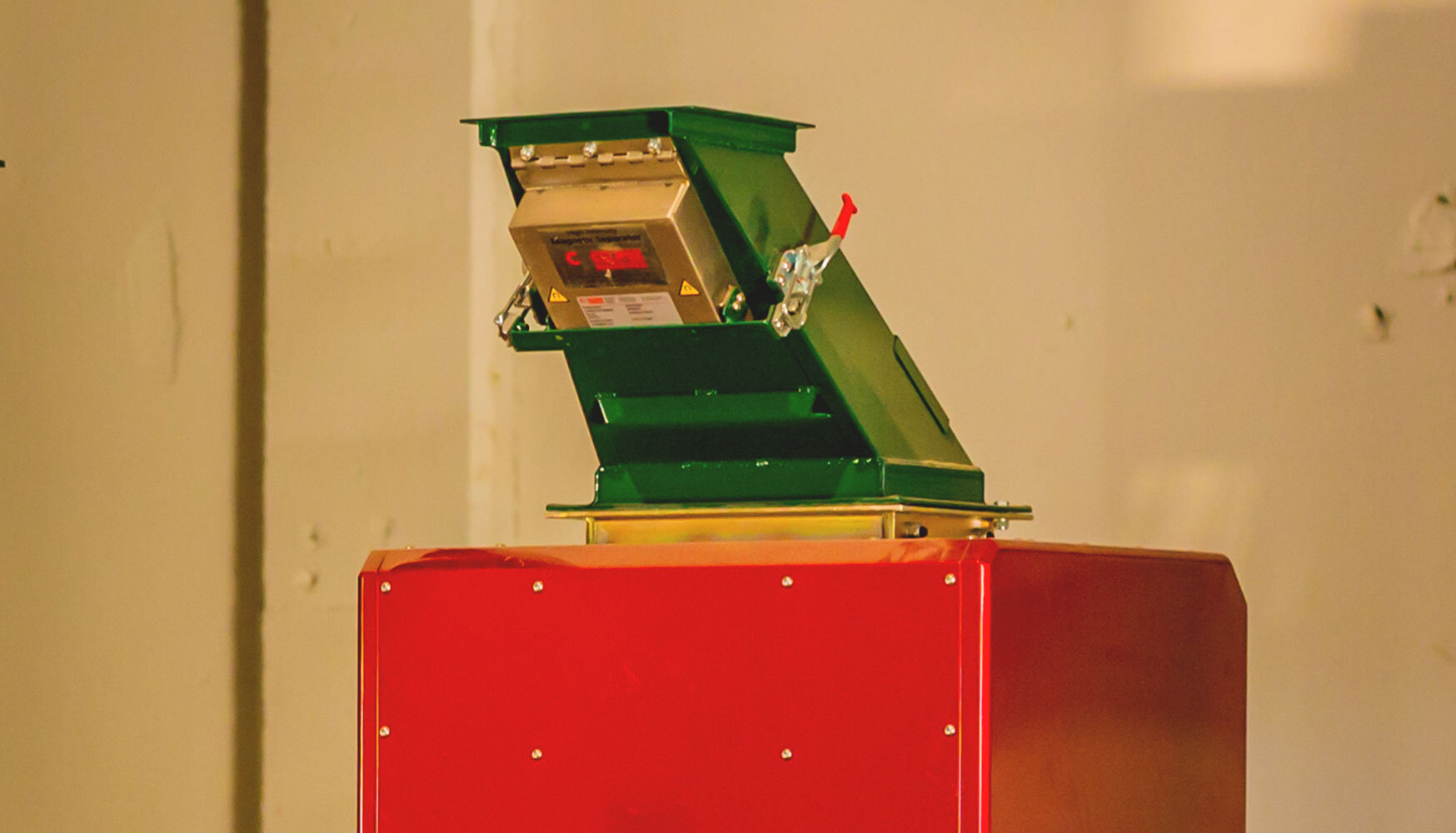

Milling

After the starch has been converted into sugar, it needs to be extracted from the barley. This is done by passing the malt through a milling machine which coarsely grinds it into a type of rough flour called grist, using a series of giant rollers. The first roller bursts the grain open and the subsequent ones grind the grist into a suitable consistency. Our mill is a 4-roller malt mill made by Alan Ruddock Precision Engineering. This grist is not as fine as flour and still contains all the elements of the husk. It is judged on three components: the husk, the grit (or middle) and the flour. The grist must be of the right consistency for mashing, so as to allow all the sugars to be absorbed by hot water while at the same time not allowing the water to simply run through. After milling, our grist is stored in a small hopper which has enough capacity for a single production run. When the hopper is full, a sensor signals for the grist to be moved to the next part of the process.

Mashing

The grist moves by a conveyor belt system into a Lauter Tun. Ours is made by Briggs and holds 2.6 tons of grain. It has a false bottom with slits to allow liquid through, but not solids. Hot water is added to the grist via the mash mixer. The ratio of grist to water is approximately 1:4 so that a hot mush like porridge is created. During the mashing process, heat from the hot water washes out the fermentable sugars, with the mash being constantly stirred using special hydraulic arms and rakes. Gravity causes the hot sugary water, known as wort, to seep down through the mash, out the false bottom, where it is recirculated back into the mash. The mash starts to behave like a sand filter and a turbidity instrument measures clarity of the wort. At the right clarity, the wort is drawn off and goes on to the next stage of the process, fermentation. The grist and water are mixed in the lauter tun three times in a process lasting around 6 hours. Each time the mash is mixed up and the temperature is increased (to around 60-70°C for the first wash, 70°C for the second and 80-90°C for the third) as a way to maximise the sugar yield. In the last wash, the sugar content of the wort is the lowest, so it is stored in the weak wort tank and used to prime the next batch in the lauter tun. The leftover mash is now called draff and is sold for animal feed. Water is very crucial for the whiskey production, as it is needed in many steps of the production including mashing, cooling and reducing the whiskey in strength. Ours is drawn from our own 120m well located beside the distillery and is passed through a filtration system supplied by Aquachem to maintain purity and consistency.

Fermentation

To convert the sugars in the wort into alcohol, a fermentation progress is necessary and therefore yeast must be added. As yeast can’t stand hot temperatures, the wort is cooled down to about 20°C before it is married with the yeast in one of our 9 fermentation tanks (or wash backs), each of which store 15,000 litres. After yeast is added to start the fermentation process, the solution, now called wash, is left in the wash back for around 48 hours. During this time the yeast spits glucose molecules in the wash, with each glucose molecule producing two ethanol molecules (which is the alcohol we need), two carbon dioxide molecules and heat. We can experience this reaction using three senses. The alcohol can be smelled. The carbon dioxide itself cannot be seen, but the reaction it causes can - the bubbles in the mash and foam produced. And then there is the resulting heat that can be felt by putting a hand on the washback. As the lauter tun produces wort every 6 hours or so, 9 tanks are required so that fermentation in the 1st tank is ready by the time the 9th is filled. During fermentation, the yeast creates a lot of CO2 and excess heat. If wash backs are placed in a cold environment the fermentation process is slower and the whiskey is said to taste better. So, all our wash backs have cooling jackets which are computer controlled to keep the liquid at a constant temperature. We also have a system to collect the CO2 to stop it building up in the distillery, plus an automated anti-foam system to monitor and manage any excess foam production. After fermentation the wash will end up with an alcohol concentration of about 6 to 10 percent. This is adequate for a nice beer, but not enough for a whiskey, so it’s time for the next step, distillation.

Heat recovery and Sustainability

As an aside, our whole plant is state of the art and is designed to be as energy efficient as possible, recovering heat from one part of the process to the next. We produce steam via a pressurized steam boiler which is gas fired. This is used as our heat source throughout the process. Steam is carried around the plant in the two largest pipes on the pipe rack. They become so hot that the pipes expand in length and must have 6 large u-bends along their length simply to absorb the movement. In terms of heat recovery, when wort is extracted from the lauter tun, our heat recovery system reduces the temperature to 20°C for fermentation using heat exchangers, with the extracted heat being used to heat the water for the next pass through the lauter tun. Similarly, hot water in various parts of the process is stored in insulated vessels for the next day’s production.

Distillation

Distillation is the process used to increase the alcohol content from the 6-10% in the wash to the final 63% of cask strength Athrú whiskey. For this process we think of the wash as being a mixture of water and alcohol. We want to remove and collect the alcohol while leaving behind some of the water in order to make a more concentrated alcohol solution. Importantly, alcohol boils at 80°C but water boils at 100°C and we can use this property to separate them. The distillation process involves heating the mixture of two liquids with different boiling points (i.e. the wash containing alcohol and water) to a mid-point and the vapour given off is then cooled and collected. As the alcohol has a lower boiling point it will begin to evaporate first and will be present in higher percentage in the vapor and the resultant collected liquid. Irish whiskey has traditionally been distilled 3 times, which is why we have 3 pot stills. Scotch, on the other hand, has traditionally been distilled only twice. As the alcohol in the wash is separated from the water, increasing the alcohol content, there is obviously less and less liquid. So, the first pot still (called the wash still) holds 15,000 litres, but the second pot still (called the feint still) is only 12,000 litres and the third (called the spirit still) is only 7,500. Our pot stills are made by Frilli and are 100% copper with a stainless-steel bottom and the liquid is heated externally by heat exchangers to help with consistency. The process starts by filling the wash into the wash still. It is then heated, and the liquid starts to evaporate. This vapour moves up the neck of the pot still (called the swan neck) where it meets a bulge (called the boiling bowl). Here some of the liquid condenses and falls back into the pot still, in a process known as reflux. Eventually, however, it makes its way into the horizontal part of the pot still called the lyne arm and from there into the condenser. The condenser is filled with small bore tubes of cold running water. When the vapour hits these it condenses back into liquid to be collected in the tank below. On its way to the tank, it passes through the glass “spirit safe” which allows the distiller to monitor performance. It also, traditionally, allowed the Revenue to verify the operation of the distillery. The first distillation in the wash stills takes approximately 4 to 7 hours. The wash still has a temperature of approximately 78°C, the evaporation point of ethanol. With each distillation, the evaporating liquid is made up of heads, hearts and tails. The heads (or foreshots) contain compounds like Acetone which, chemically, is too harsh and smells bad. The tails (or faints) have a bitter taste and are also discarded. The hearts (or spirit) contain primarily ethanol and are rich in flavour, smell great and taste smooth. This is the liquid that will eventually end up as whiskey. In this first pot still an alcohol solution is produced with about 20 to 25 alcohol by volume (ABV). It is called the low wines. This is then filled into the feint still and the process repeated, this time producing an alcohol solution with about 30 to 35 ABV. It is called the feints. This is then filled into the spirit still and the process repeated a third time, producing a colourless spirit which has a high alcohol content of around 63% ABV. This will eventually become cask strength Athrú whiskey. Alcohol that undergoes triple distillation is lighter in colour while maintaining a higher strength of spirit, resulting in a cleaner, crisper taste.

Casking

The distillate from the 3rd pot still ends up in the spirit receiver. We then pump it into a special stainless-steel tank in the yard. This is primarily because it is now a flammable liquid, so we want to keep it away from anything combustible (including our barrels). From here the liquid is pumped into ex-Bourbon casks and moved to our warehouse for 3 years and 1 day. Only then can it be called whiskey!

Cleaning

Clean-in-place (CIP) is an automated method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly. Repeatable, reliable, and effective cleaning is of the utmost importance in the distillery process, which is effectively a food grade environment. In order to adequately clean processing equipment, the equipment is designed with smooth stainless-steel surfaces and interconnecting piping that has cleanable joints. The chemical properties of the cleaning agents must properly interact with the chemical and physical properties of the residues being removed. Each of our vessels has a stainless-steel spray head suspended inside. We put pressurised liquid through this, which sprays the inside of each vessel. First, we pre-rinse with purified water to wet the interior of the vessel and remove residue. It also provides a non-chemical pressure test of the CIP flow path. Then a caustic solution is passed through to clean the vessel. A second rinse is performed before a mild acidic solution is passed through to remove mineral precipitates and protein residues. Lastly, a final rinse flushes out residual cleaning agents. Air is then blown through to remove moisture remaining after the CIP cycle.